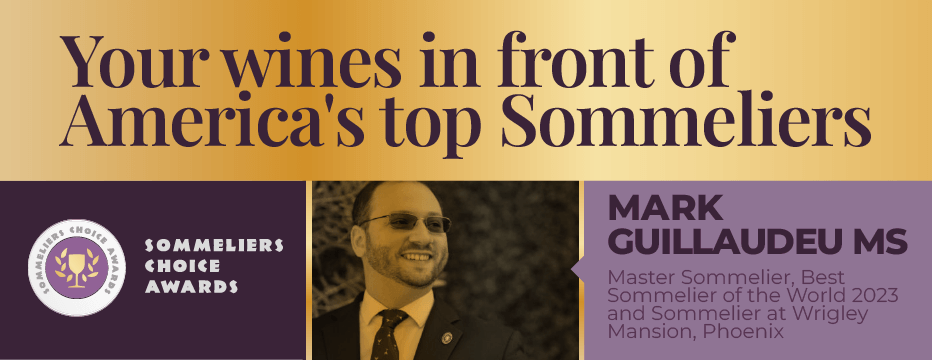

Sommeliers Choice Awards 2023 Winners

Secrets to Sorting Out Price and Cutting Costs

A good price for the company – on ingredients, packaging, manufacturing, and distribution – means the best price for their customers.

If pricing is one of the most important factors in running and growing a successful beverage company, why does it trip up so many entrepreneurs? Typically, it’s because they don’t plan ahead. A good price for the company – on ingredients, packaging, manufacturing, and distribution – means the best price for their customers. In order to get a good price, a beverage startup must plan early for their outcome rather than winging it and hope for the best.

The Nuts and Bolts of Price

One of the biggest mistakes any sort of food or drink company makes is failing to understand how their overall cost gets built. Simply put: everything has a cost to it. Everything that happens will cost money before the product finds its way onto shelves. Company owners have to know what those costs are in order to plan accordingly.

Imagine: if the cost of goods for a bottle of beer is $1, the price on the shelf will be $3 or $4 by the time everyone else takes their cut. In the beverage industry, costs tend to run higher than in the food industry, so a 4x increase is a healthy expectation.

Costs associated with ingredients will affect the overall price. This isn’t as simple as “How much do the ingredients themselves cost?” Instead, the questions that should be asked are “How much do they cost after they’ve been delivered to the factory?” and “How much does it cost to get them out of the plant and off to the next step in the process?”

Beyond Raw Materials

What about packaging? Heavier glass wine bottles signify that the product inside is high-end, but they cost more. Natural corks also denote a quality product, but they’re more pricey than their synthetic counterparts or screw caps. All of these decisions will depend on whether a wine is destined to be land at a $65 per-bottle price point, or if it will be a more affordable $18 per bottle.

Printing labels and manufacturing cases also bumps the bill higher, as does warehousing product. Another cost that often gets overlooked in the initial stages? Outbound distribution, which contract manufacturers won’t do for you.

For instance, if a product’s cost is $8 a case, minus distribution, someone new to the industry would be surprised at how much distribution costs could drive that cost up. Distributing via LTL* is more pricey, as the charge is per pallet. If the cost is $400 a pallet and there are 144 cases on one pallet, that adds an additional $2.78 to the case price.

FTL** meanwhile is a much more cost-effective way to distribute goods. While $2,000 per truckload may sound expensive, a truck full of double-stacked pallets will hold 52 pallets, which translates to $0.27 a case – huge savings over LTL. This is one of many examples of how as a company and its production grows, its prices go down.

Cost doesn’t end once the product is on the truck. The distributor will take their cut for their reps to put your product in front of retailers...who will also demand a margin in order to showcase the product in the most attractive location possible. Endcaps and special displays will run those prices even higher. Add to this the cost of ongoing promotions, as well as staffing and providing product for tastings and promotional events, and the final price-on-shelf gets pushed even higher.

Cost Structure Starts at R&D

Figuring out cost isn’t a process that begins just before a company is ready to start production. It needs to start in the early stages during research and development. Every decision made at this stage will have an impact on cost later, from product type to ingredients, as well as the manufacturing process, overall complexity, and scale of production.

The need for manufacturing is another thing to factor during the R&D process. This is an area where planning really is key. Many startups kick off with the idea that they’ll manufacture their own product. They may have come up with a way to make their product in a way that no one else does it. Maybe they enjoy the process. Some companies can even pull off their own manufacturing.

For others, this idea seems good on paper but doesn’t play out well in reality. Most entrepreneurs aren’t manufacturers; they do better at getting out and preaching the gospel of their product than they do actually making said product. Self-manufacturing can work well until orders ramp up and a startup can no longer keep up with demand.

The other concern is with developing a unique and never-been-seen-before manufacturing process. Making a product in a way that no one else does it means that no one else is doing it – a real problem when it comes time to find a co-manufacturer. It’s always a safe bet to assume that a company will need a co-manufacturer so that they can factor in the costs of using one and create a product that’s easily manufactured in most standard facilities.

Manufacturing Savings: Relationships Are Everything

As with all of the other steps in the process, finding and working with a manufacturer takes planning in order to reduce costs. Why is this?

Manufacturers tend to offer more attractive prices to companies that can work on longer production timelines, saving their steepest charges for those who need their products made in a hurry. If a company contacts a co-manufacturer and demanding a quick turnaround, this tells the manufacturer that the company hasn’t planned ahead, is likely to be a disorganized problem customer, and is in a bind and likely has no other options. And up goes the price.

Having a good relationship with a co-manufacturer is a great way to ensure that a company continues getting the best price. Respecting lead times and constant communication are two signs of a good customer. Another way to score points with a manufacturer is to tell them when things are going right and not only when they’ve gone wrong, as they don’t usually hear the success stories.

Another key to savings is knowing when to cut ties with a manufacturer and move on. This will happen as a company grows because a co-manufacturer that can help a smaller beverage company might not be able to help that same company as it grows. Switching manufacturers is a normal strategic part of cutting cost. It’s important for a company not to overcommit to a manufacturer and prevent being able to renegotiate or move on after they've grown and had more leverage.

In the end, pricing is all about knowing and controlling cost, as well as understanding that there is a cost associated with every imaginable aspect of creating, moving, and selling a product. By planning ahead of time, beverage companies can control costs, rather than simply sitting back and allow those costs to pile up around them.

* LTL: “Less-than-truckload.” This means that a shipment won’t take up all of the available space on the truck.

** FTL: “Full truckload.” With this kind of shipping, each load fills up the entire truck.